ICE® Reintroduces Partner and Rig Training

February 1, 2023

ICE® Reintroduces Partner and Rig Training

Editor: Debbie Reaney

Within a world of many choices, ICE® has developed a rigorous process to identify client necessity. Since 1974, the team has implemented small batch theory into our production facilitating client guided innovation and technologically advanced equipment. Choosing the right partner to enhance a one stop foundation and ground improvement service, sales and rentals team is key to staying on track with the International Construction Equipment, Inc. vision.

In foundation and ground improvement it is important to have the added benefit of both multiuse rigid and articulated hydraulic crawler drilling rigs. Knowing this, ICE® prioritized finding a drilling product line with suitability for several types of specialized work, such as ground consolidation, anchor drilling, geotechnical works, water well drilling and geothermal energy. With almost 40 models to offer, ICE® chose to represent the Comacchio drilling rigs to offer the industry's most comprehensive line of deep foundation equipment available. Each rig can be used for rotary and rotary-percussive drilling, for single head or double head applications and much more.

ICE® customers have suggested the MC-22A is a diverse and highly adaptable duplexing drill rig. Nicholson Construction has been able to utilize this unit and take advantage of many of its features in recent years. For instance, while at the Prairie du Sac dam in mid-state Wisconsin, MC-22A was part of fleet of four rigs that completed a rigorous schedule on time and with great accuracy. "The ability to articulate the mast 90-degrees to the drill body while also maintaining a 45-degree batter with no bleed off during the drilling process was key to maintaining accuracy. In addition, utilizing the innovative hydraulic rod and casing carousel, we were able to eliminate an additional piece of equipment reducing the weight impacting the structure of the over 100-year-old dam." explains Daniel Mirt, Nicholson Operations Manager. During the third year of this project, Nicholson improved the process by mounting a Moyno® water pump across the body. Doing so allowed them to eliminate another piece of equipment and the time it took to move it. This also increased efficiency and helped reduce costs. The MC-22A is a fully remote-controlled drill, which permits the operator to safely move about the deck to see all aspects of the drilling process.

The MC Line offers ranges from compact units weighing just over 3-tons, designed for operation in low headroom and restricted access sites, to large drilling rigs weighing up to 30-tons and providing over 200 kW of power, designed for the most demanding jobs and heavy-duty drilling methodologies, including double head applications. ICE® demands products they represent to have a focus on productivity and safety. Comacchio MC line rigs can offer an array of automated rods and case handling solutions eliminating the risk of injury. "While at the dam it was required to hold more casing and rods than the standard carousel, this posed no issue for the MC-22A as we were able to remove and increase the quantity by changing the pods that hold the casing and rods easily." expressed Mirt. On the upstream side of the dam, it was determined the drill would be fed by an excavator mounted casing and rod manipulator due to the intricacies of working from a barge. The moderate size of the MC-22A allowed for both pieces of equipment to share the restricted footprint of the barges and overcome the complexities. The drill was able to maintain good reach over the operator deck handrail and complete the drilling of micro-piles through multiple levels of the dam. This adaptability allowed Nicholson to be efficient and on schedule.

The MC-22A can be configured as a single or double rotary head and is a small-diameter drill rig used particularly for making small-diameter bored piles and rock anchors. Available for sale and rent with a wide selection of rotary heads, hydraulic hammers, water and mud pumps, and rod carousels, the MC-22A is suitable for any type of rotary and rotary-percussive drilling. The MC-22A with rod and casing carousel is capable of handling drill rods inside of casing and has the unique ability to drill cased holes with only one operator. This setup can provide advantages over other rigs in that others often require 3 personnel to do the same work when utilizing casing. In addition to the operator advantages, the rig can achieve production levels up to 1,200 ft (about 365.76 m). drill depth per day, which is critical for large-scale jobs.

Like all drill rigs that ICE® carries, the MC-22A is designed, primarily, with a driller's perspective. The engines comply with the current European and American (EPA and CARB) legislation regarding emissions. All MC drilling rigs can be equipped with a series of innovative systems that focus on operator safety while simplifying the automation processes of drilling. "Not only do the Comacchio rigs enhance safety standards, but these designs also enable efficient maintenance and repair platforms for drilling mechanics." explains Scott Crews, ICE® Drilling Division Director.

ICE (International Construction Equipment,) ® will be highlighting a few drill rigs like this piece of equipment at the 2023 Con-Expo event in Las Vegas, NV this March. It will be shown demonstrating proper safety procedures while placing tiebacks. ICE® Trainers will be presenting on-site training modules during the expo with PDH credits available. ICE® will be partnering with engineering firms and other suppliers to host a comprehensive training session. Educational sign-ups are available on the ICE® website. Additional deep foundation equipment to be spotlighted includes the ICE® Zero Resonance Vibratory Hammer, Comacchio CH-150 mini-caisson rig & the MC-8D, a low-headroom drill and further training opportunities like sessions on pile driving on a batter.

Media Contact-

Pollyanna Cunningham, MA, MBA

Vice President Marketing, Brand and Media Relations / Vice President IT and IT Comm

ICE® - International Construction Equipment, Inc

Office - 704-821-8200

Email - marketing@iceusa.com

ICE® wishes a "Bon Voyage" to Mike Robinson!

January 31, 2023

ICE® wishes a "Bon Voyage" to Mike Robinson!

Editor: Debbie Reaney

In late February, early March of 2023, International Construction Equipment, Inc. will be saying goodbye to an outstanding sales leader and mentor, Mike Robinson. As Mr. Robinson retires, we want to share some of his insights and memories. Grandfather of 5 (3 boys/2 girls), Mike says his 13-year-old grandson is interested in tinkering and could be the next big innovator in the industry. The others are younger, so he is still holding out hope they might take an interest in pile driving and drilling industry. Robinson's youngest son is an electrician and his oldest is a welder by trade, but he also owns his own fabrication shop and business. "Be a leader, not a follower," is something he has instilled in his children and grandchildren along with making sure they knew there were consequences for every decision, "When you are out and about- whatever you are doing, if you are ashamed to come home and tell your parents what you were doing, you shouldn't be doing it." Wise words that we all should contemplate.

Almost 30 years ago, Mike hired and trained his nephew, long time ICE® employee Shawn Robinson, starting him out washing bolts for the machines and encouraging him to learn as much as he could from the ground up. "If your equipment breaks, it was made by people -things happen, be fair." Shawn appears to have taken his uncle's advice to heart, expressing that, "Mike Robinson was the single biggest influence in my career, he saw potential in a 19-year-old kid who did not know anything... Now, 29 years later, I am proud to be part of his legacy. Uncle Mike can be a difficult man sometimes, but he has always treated ICE® customers as if they were his own family. His upfront loyalty and candor will be missed."

Mike Robinson's father drove pile for over 50 years working for a local company in North Carolina. Mike started working there as a young man doing maintenance. Robinson says he did not grow up with a passion for pile, but he did develop a love for his work. His contribution to the USA as a Marine and some work in the forklift industry altered his course briefly, but with guidance and mentorship from his dad he easily found his footing in the pile driving world.

"Give your customers the best equipment for the job, and they will always come back to you," was a piece of advice from his father that Mike still puts into practice and what he says has made him successful. Robinson feels that is why many of his customers love ICE®. He is always putting the customer's best interest first by selling/renting what they need versus what they think they need. It is all about knowing the job, knowing the equipment, and knowing the customer. "It's not ever about the money," Robinson says. Mike started as a mechanics helper at 15 and worked on his own car figuring it out along the way. After high school he attended two technical training schools within the Marine Corp, which placed him firmly on his path. Robinson says he has always been intrigued with how things work and found he had a natural affinity for tinkering. This has served him well in the industry, consistently staying on top of innovative technology and learning how the latest equipment works. Reading manuals and case studies is part of his normal routine. As a young man, Robinson worked on servicing cranes for his father. He had no formal knowledge starting out, but his natural inclination of mechanics, continued studies and motivation to read everything, made him good at everything he touched.

In the 80's Mike became a service tech for a company that was a distributor for International Construction Equipment, Inc (ICE®). After 12 years in the field, Robinson was approached by Christian Cunningham, ICE®, CEO, and was hired in 1999 as a service manager. Not long afterwards, he was asked to switch roles to become the Branch Sales & Service Manager in the Virginia area. Robinson's wife of 44 years, Debbie, was thrilled with the change and was ready to support Mike in his next big adventure.

Mike stated that working for ICE® has afforded him many opportunities to sharpen his skills with most industry knowledge happening on the job and out in the field. Robinson feels that his service experience gave him insight to best support ICE® Customers and would strongly encourage anyone who wants to excel in their field to learn and train as much about their industry and products as possible. Knowing what the equipment can do is necessary to provide the best customer service. If you have not heard, ICE® 's culture is built on this principle, as most of their sales team have a strong background in construction management, service, parts, or engineering within the pile driving industry. We have a large arsenal of experts to pull information from to share with our customers.

Some of Robinson's biggest challenges over his 30+ years has been a noticeable shift in industry culture. He expressed the feeling that newer subcontractors and pile drivers need a bit more training and service help than in the past. All jobs are different. But one common trend is the need for training and Mike always offers maintenance, safety and set up procedure training from start to finish. Like all ICE® sales team members, Robinson loves to take his time to make sure the crew knows how to put the equipment together, get a pile stood up, get the hammer setup safely, and most importantly making sure they understand how the soil can and will affect the job.

Robinson's territory encompasses West Virginia to Georgia. When asked about his sales approach, Robinson always asks, before suggesting a drill or pile driver, "where's the job?" The soil requirements are varied and knowing what type of equipment will work best in certain situations is imperative. This is another reason why ICE® believes it is important to have some service or engineering background prior to sales. Inquiries about Mike's greatest successes over the years were answered with reluctance and grace, feeling that all pile driving jobs completed were a tremendous success for the industry. However, after some prodding, Mike acknowledged that he was immensely proud of the contractors he had the ICE® marketing team write up for PDCA "Project of the Year" submissions over the years.

Balfour Beatty out of Wilmington and United out of Great Falls, SC are two of his favorite clients. He has made many good friends in the industry and will deeply miss that camaraderie. That sentiment is echoed by Jay Boyd, Operations Manager at Balfour Beatty Infrastructure, "I have known Mike for over 30 years, and I wholeheartedly agree that he is a true industry pioneer." When they first met in 1988, Boyd was a firefighter and did not know a thing about construction let alone pile drivers. That very day Mike took him under his wing and took the time to not only talk to Jay about the machines, but Robinson also taught Boyd all about the various hammers, including how to time a steam operated pump which they ran on back then. "The time he took meant the world to me and has absolutely been a factor in my own personal success. Every project Balfour Beatty SE has, we look to the ICE® team for advice, guidance, and equipment to assist us in making our jobs not only safe but on time and profitable. Robinson and the ICE® team are our go-to guys, and we are thankful for our relationship. ICE® is known in the industry for a sales team that possesses hands on knowledge of safety and pile driving best practices, Mike is one of those ICE® leaders that not only knows the material but is a born teacher for the driven pile industry. I am honored to have trained and worked with him for the past 30+ years."

Robinson is not sure what he will be doing once retirement is a reality, but for now he hopes to be able to just relax and enjoy his greatest title, grandpa.

Best wishes to Mike Robinson. You will be missed.

Pollyanna Cunningham, MA, MBA

Vice President Marketing, Brand and Media Relations

ICE® - International Construction Equipment, Inc

Office - 704-821-8200

Email - marketing@iceusa.com

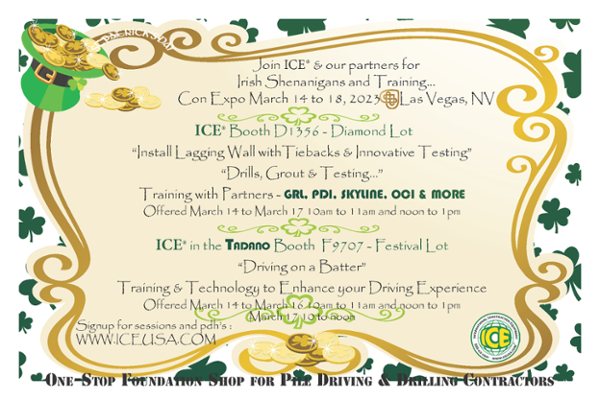

Join ICE® & our partners for Irish Shenanigans and Training at Con-Expo 2023!

January 26, 2023

Join ICE® & our partners for

Irish Shenanigans and Training...

at Con Expo from March 14 to 18, 2023 in Las Vegas, NV!

ICE® Booth D1356 - Diamond Lot

"Install Lagging Wall withTiebacks & Innovative Testing"

"Drills, Grout & Testing..."

Training with Partners - GRL, PDI, SKYLINE, OCI & MORE

Offered March 14 to March 17 10am to 11am and noon to 1pm

ICE® in the Tadano Booth F9707 - Festival Lot

"Driving on a Batter"

Training & Technology to Enhance your Driving Experience

Offered March 14 to March 16 10am to 11am and noon to 1pm

March 17 10 to noon

Signup for sessions and pdh's now. These trainings will fill up :

https://www.iceusa.com/events/

Media Contact-

Pollyanna Cunningham, MA, MBA

Vice President Marketing, Brand and Media Relations

Vice President IT and IT Comm

ICE® - International Construction Equipment, Inc

Office - 704-821-8200

Email - marketing@iceusa.com

Investing In Safe Water Infrastructure

January 20, 2023

Investing In Safe Water Infrastructure

Editor: Allison Braswell

The Allegheny Valley Joint Sewer Authority (AVJSA) in Pennsylvania is taking action to protect the Allegheny River from discharges of treated sewage and stormwater. By 2023, the facility plans to expand its sewage treatment capacity from the current 5.5 million gallons (about 20819755 L) a day to 8 million gallons (about 30283280 L). Mandated by the EPA, this $75-million project is part of a nationwide effort to prevent raw sewage overflows and inadequately controlled stormwater from discharging into rivers, streams, lakes, and other waterways. AVJSA currently has pump stations in three divisions of Allegheny County (Cheswick, Harmar, and Springdale) that each date back to 1980. It was determined that a new pump station at Cheswick plus a new sewage trunk line from Springdale to Harmar is needed to begin fostering the viability of the county's water and wastewater operations under the mandate.

Mele & Mele & Sons was awarded the opportunity to construct the new pump station. The equipment the contractor initially used could not get the NZ19 sheet piles driven to the 70' (ft) depths required for the foundation shoring--so they decided to give the equipment experts at ICE® a call. After ICE® reviewed the soils using a WEAP analysis, they determined the need for an ICE® D-50 Diesel Impact Hammer to accomplish the task. Despite working in a snug workspace when installing the NZ19 sheet pile, this powerful hammer succeeded at driving the sheets to the specified depth quickly, easily, and safely.

The expansion is set to be complete by 2026. Excellent job to Mele & Mele & Sons for addressing Allegheny County's emerging contaminants and helping our nation take a step closer to a world of more clean and resilient water resources. International Construction Equipment, Inc. is proud to have been a small part of this much-needed environmental clean-up.

Media Contact-

Pollyanna Cunningham, MA, MBA

Vice President Marketing, Brand and Media Relations

Vice President IT and IT Comm

ICE® - International Construction Equipment, Inc

Office - 704-821-8200

Email - marketing@iceusa.com

Mountain Ridges & Temporary Bridges

January 4, 2023 Mountain Ridges & Temporary Bridges

Mountain Ridges & Temporary Bridges

Editor: Allison Braswell

What better place to enjoy nature while working in construction than at Glacier National Park, MT--where the Battle Ridge Construction team took in breathtaking views of the Rocky Mountains as they used an ICE® 28B Vibratory Hammer to pull four 16" (in) steel piles of around 20' (ft) long from a temporary bridge as part of the park's rehabilitation work on 13 bridges.

The park's bridge improvements include timber pile and curb replacement, concrete repair, erosion control measures and more, requiring alternative site access for tourists for the duration of the project. Temporary bridges are a popular option for diverting traffic flow during construction on permanent bridges, both with vehicles and pedestrians. They can be installed adjacent to the existing bridge, which allows for convenient rerouting with no disruptions. When the new bridge is completed, the temporary bridge is removed and even sometimes reused on another job. However, it is important to keep in mind that these bridges are designed to be temporary ways of transportation for a reason. They are not suited for nearly the same amount of traffic use as permanent bridges, so frequent examinations are necessary to ensure that the bridge is able to support the weight of daily traffic, which can slow down progress with your project. In this case, the ICE® 28B succeeded at quickly extracting the pile to remove the temporary bridge, accelerating the pace of the improvement efforts at Glacier National Park.

The $8.9 million-worth of bridge reconstruction will last through May 2023--Just in time for the peak season when 3 million people are expected to visit the park to enjoy activities like horseback riding, hiking trails, and boat tours. International Construction Equipment, Inc appreciates Battle Ridge Construction for the opportunity to help enhance tourists' experience as they soak up Montana's wildflower-filled meadows, sparkling lakes, and glacial-carved natural giants.

Learn more about the ICE® 28B.

Media Contact-

Pollyanna Cunningham, MA, MBA

Vice President Marketing, Brand and Media Relations

Vice President IT and IT Comm

ICE® - International Construction Equipment, Inc

Office - 704-821-8200

Email - marketing@iceusa.com